Optical Systems

OVERVIEW

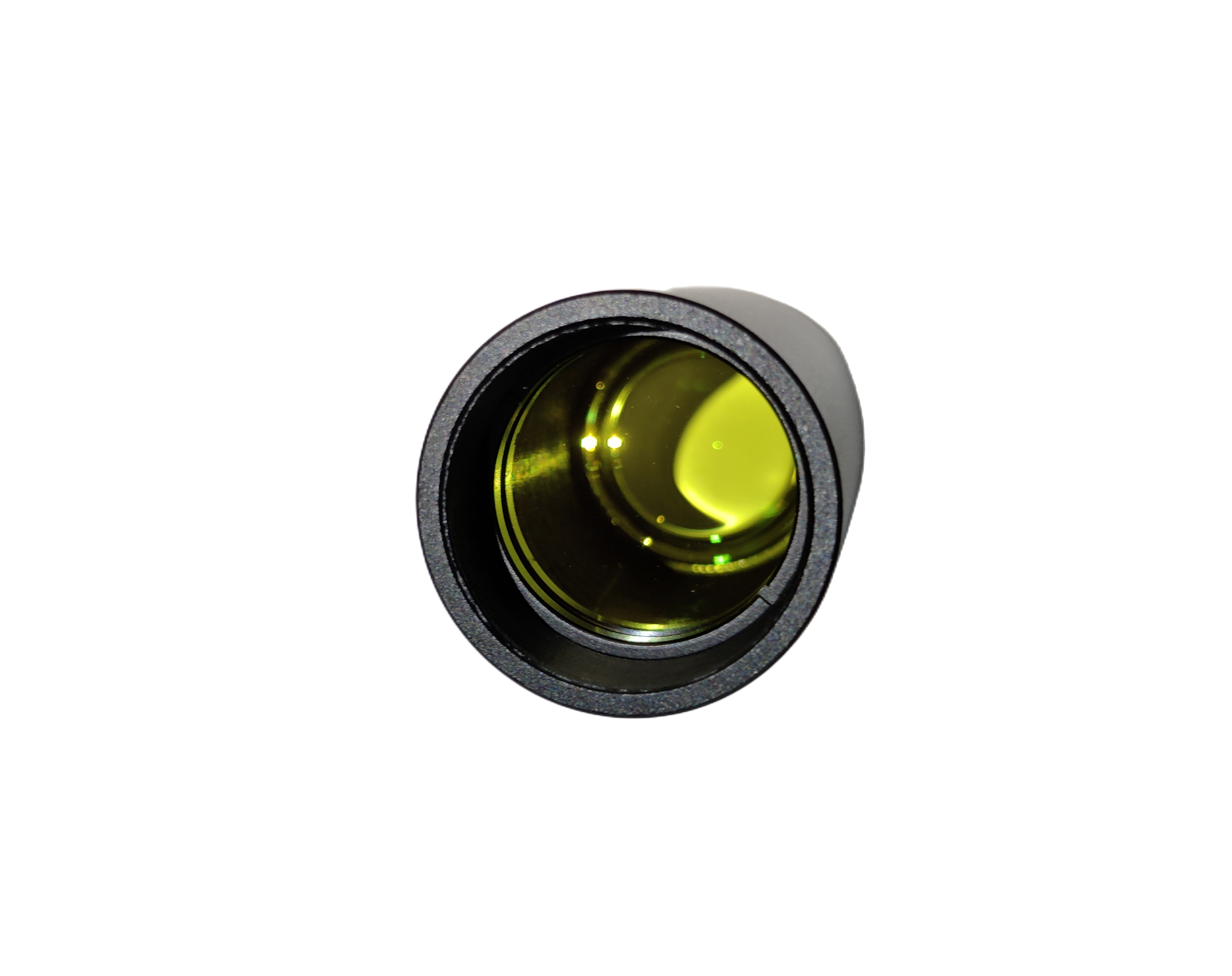

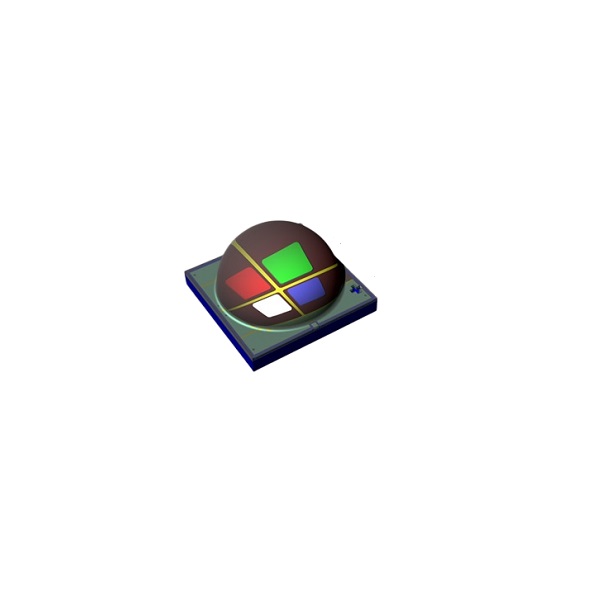

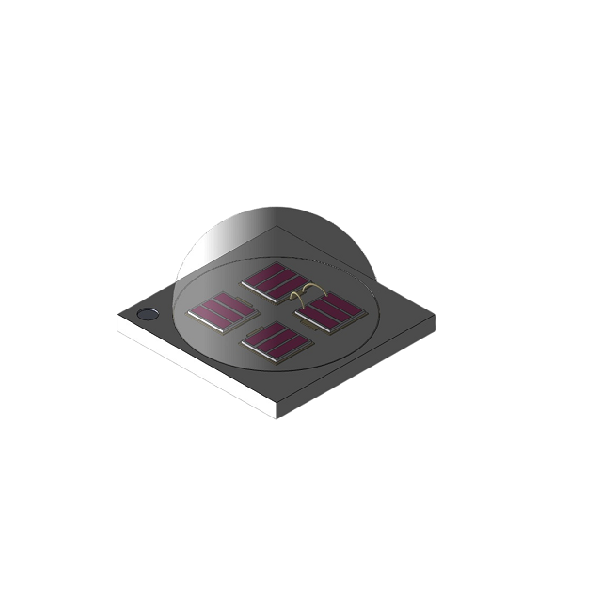

Optical Systems are the optical components of LED light sources, usually made of transparent materials such as glass or plastic. Its function is to focus or scatter the light emitted by the LED to achieve the desired optical effect. LED optical systems have applications in a variety of industries and environments.

Optical Systems &PRODUCT

| Product | Power/W | Peak/nm | If,mA TEST | VF/V | SIZE | Mounting diameter | Socket length | optical thickness | surface treatment | thread | Part No. |

| QDF1SM8A-B | 0.2 | 365-800nm | 20-60MA | 1.5-4V | Ø1 | φ25.4mm | 8.0mm | 6.0mm | black anodized | Internal and external thread | YLTGFZ01 |

| QDF1SM8A1-B | 0.2 | 365-800nm | 20-60MA | 1.5-4V | Ø1 | φ25.4mm | 12.5 mm | 10.5 mm | black anodized | Internal and external thread | YLTGFZ02 |

| QDF1SM12.5A-B | 0.2 | 365-800nm | 20-60MA | 1.5-4V | Ø1 | φ25.4mm | 12.5 mm | 10.5 mm | black anodized | Internal and external thread | YLTGFZ03 |

| QDF1SM25A-B | 0.2 | 365-800nm | 20-60MA | 1.5-4V | Ø1 | φ25.4mm | 25 mm | 23 mm | black anodized | Internal and external thread | YLTGFZ04 |

| QDF1SM50A-B | 0.2 | 365-800nm | 20-60MA | 1.5-4V | Ø1 | φ25.4mm | 50 mm | 48mm | black anodized | Internal and external thread | YLTGFZ05 |

| QDF1SM50C2-B | 0.2 | 365-800nm | 20-60MA | 1.5-4V | Ø1 | φ25.4mm | 50 mm | 48 mm | black anodized | Internal and external thread | YLTGFZ06 |

| QDF1SM75A-B | 0.2 | 365-800nm | 20-60MA | 1.5-4V | Ø1 | φ25.4mm | 75 mm | 73 mm | black anodized | Internal and external thread | YLTGFZ07 |

| QDF1SM8B-B | 0.2 | 365-800nm | 20-60MA | 1.5-4V | Ø1 | φ25.4mm | 8.0 mm | 4.0 mm | black anodized | internal thread | YLTGFZ08 |

| QDF1SM12.5B-B | 0.2 | 365-800nm | 20-60MA | 1.5-4V | Ø1 | φ25.4mm | 12.5 mm | 8.5 mm | black anodized | internal thread | YLTGFZ09 |

| QDF1SM25B-B | 0.2 | 365-800nm | 20-60MA | 1.5-4V | Ø1 | φ25.4mm | 25 mm | 21 mm | black anodized | internal thread | YLTGFZ10 |

| QDF1SM50B-B | 0.2 | 365-800nm | 20-60MA | 1.5-4V | Ø1 | φ25.4mm | 50 mm | 46 mm | black anodized | internal thread | YLTGFZ11 |

| QDF1SM8C-B | 0.2 | 365-800nm | 20-60MA | 1.5-4V | Ø1 | φ25.4mm | 8.0 mm | 23.5mm | black anodized | external thread | YLTGFZ12 |

| QDF1SM12.5C-B | 0.2 | 365-800nm | 20-60MA | 1.5-4V | Ø1 | φ25.4mm | 12.5 mm | 23.5mm | black anodized | external thread | YLTGFZ13 |

| QDF1SM25C-B | 0.2 | 365-800nm | 20-60MA | 1.5-4V | Ø1 | φ25.4mm | 25 mm | 23.5mm | black anodized | external thread | YLTGFZ14 |

| QDF1SM50C-B | 0.2 | 365-800nm | 20-60MA | 1.5-4V | Ø1 | φ25.4mm | 50 mm | 23.5mm | black anodized | external thread | YLTGFZ15 |

| QDF2SM8A-B | 0.2 | 365-800nm | 20-60MA | 1.5-4V | Ø2 | φ50.8mm | 8.0mm | 6.0 mm | black anodized | Internal and external thread | YLTGFZ16 |

| QDF2SM25A-B | 0.2 | 365-800nm | 20-60MA | 1.5-4V | Ø2 | φ50.8mm | 25 mm | 23.0 mm | black anodized | Internal and external thread | YLTGFZ17 |

| QDF2SM25B-B | 0.2 | 365-800nm | 20-60MA | 1.5-4V | Ø2 | φ50.8mm | 25 mm | 21.0 mm | black anodized | internal thread | YLTGFZ18 |

| QDF2SM25C-B | 0.2 | 365-800nm | 20-60MA | 1.5-4V | Ø2 | φ50.8mm | 25 mm | 48.3 mm | black anodized | external thread | YLTGFZ19 |

| QDF1SM8A-B | 3 | 365-800nm | 300-700MA | 1.5-4V | Ø1 | φ25.4mm | 8.0mm | 6.0mm | black anodized | Internal and external thread | YLTGFZ20 |

| QDF1SM8A1-B | 3 | 365-800nm | 300-700MA | 1.5-4V | Ø1 | φ25.4mm | 12.5 mm | 10.5 mm | black anodized | Internal and external thread | YLTGFZ21 |

| QDF1SM12.5A-B | 3 | 365-800nm | 300-700MA | 1.5-4V | Ø1 | φ25.4mm | 12.5 mm | 10.5 mm | black anodized | Internal and external thread | YLTGFZ22 |

| QDF1SM25A-B | 3 | 365-800nm | 300-700MA | 1.5-4V | Ø1 | φ25.4mm | 25 mm | 23 mm | black anodized | Internal and external thread | YLTGFZ23 |

| QDF1SM50A-B | 3 | 365-800nm | 300-700MA | 1.5-4V | Ø1 | φ25.4mm | 50 mm | 48mm | black anodized | Internal and external thread | YLTGFZ24 |

| QDF1SM50C2-B | 3 | 365-800nm | 300-700MA | 1.5-4V | Ø1 | φ25.4mm | 50 mm | 48 mm | black anodized | Internal and external thread | YLTGFZ25 |

| QDF1SM75A-B | 3 | 365-800nm | 300-700MA | 1.5-4V | Ø1 | φ25.4mm | 75 mm | 73 mm | black anodized | Internal and external thread | YLTGFZ26 |

| QDF1SM8B-B | 3 | 365-800nm | 300-700MA | 1.5-4V | Ø1 | φ25.4mm | 8.0 mm | 4.0 mm | black anodized | internal thread | YLTGFZ27 |

| QDF1SM12.5B-B | 3 | 365-800nm | 300-700MA | 1.5-4V | Ø1 | φ25.4mm | 12.5 mm | 8.5 mm | black anodized | internal thread | YLTGFZ28 |

| QDF1SM25B-B | 3 | 365-800nm | 300-700MA | 1.5-4V | Ø1 | φ25.4mm | 25 mm | 21 mm | black anodized | internal thread | YLTGFZ29 |

| QDF1SM50B-B | 3 | 365-800nm | 300-700MA | 1.5-4V | Ø1 | φ25.4mm | 50 mm | 46 mm | black anodized | internal thread | YLTGFZ30 |

| QDF1SM8C-B | 3 | 365-800nm | 300-700MA | 1.5-4V | Ø1 | φ25.4mm | 8.0 mm | 23.5mm | black anodized | external thread | YLTGFZ31 |

| QDF1SM12.5C-B | 3 | 365-800nm | 300-700MA | 1.5-4V | Ø1 | φ25.4mm | 12.5 mm | 23.5mm | black anodized | external thread | YLTGFZ32 |

| QDF1SM25C-B | 3 | 365-800nm | 300-700MA | 1.5-4V | Ø1 | φ25.4mm | 25 mm | 23.5mm | black anodized | external thread | YLTGFZ33 |

| QDF1SM50C-B | 3 | 365-800nm | 300-700MA | 1.5-4V | Ø1 | φ25.4mm | 50 mm | 23.5mm | black anodized | external thread | YLTGFZ34 |

| QDF2SM8A-B | 3 | 365-800nm | 300-700MA | 1.5-4V | Ø2 | φ50.8mm | 8.0mm | 6.0 mm | black anodized | Internal and external thread | YLTGFZ35 |

| QDF2SM25A-B | 3 | 365-800nm | 300-700MA | 1.5-4V | Ø2 | φ50.8mm | 25 mm | 23.0 mm | black anodized | Internal and external thread | YLTGFZ36 |

| QDF2SM25B-B | 3 | 365-800nm | 300-700MA | 1.5-4V | Ø2 | φ50.8mm | 25 mm | 21.0 mm | black anodized | internal thread | YLTGFZ37 |

| QDF2SM25C-B | 3 | 365-800nm | 300-700MA | 1.5-4V | Ø2 | φ50.8mm | 25 mm | 48.3 mm | black anodized | external thread | YLTGFZ38 |

FEATURES

Optical Systems usually come in different shapes and sizes to suit different application scenarios.

For example, shapes such as circle, square, rectangle, ellipse can be used for different lighting needs,

Such as spotlights, floodlights, floodlights, parallel lights, etc. In addition, LED Light Sleeves can also be customized to meet specific optical requirements.

The design and manufacture of LED optical sleeves need to consider many factors, such as optical performance, material selection, processing technology, etc., so careful calculation and testing are usually required to ensure that it can provide high-quality optical effects.

Advantages of BENEFITS:

Optical Systems are advanced lighting solutions that deliver high performance and energy efficiency. These systems utilize LED technology to provide superior lighting for a variety of applications.

The performance of the LED optics is unrivaled, with high lumen output and excellent color rendering. These systems are available in a variety of color temperatures, allowing lighting options to be tailored to suit different environments.

In terms of product design, the LED optical system is compact, light in weight, and easy to install and maintain. They are also extremely durable and have a long lifespan, reducing the need for frequent replacements.

One of the key features of LED optics is its adjustable beam angle, which allows for precise lighting control. This allows users to direct light exactly where it is needed, improving visibility and reducing light waste.

APPLICATION

Medical optical components are an important part of modern medical technology. It includes various types of optical devices used in the diagnosis, treatment and management of different medical conditions. Optical technology enables physicians to perform detailed examinations and treat patients with greater accuracy and precision.

- Application of PCR optical lens tube system in medical treatment:

PCR technology is widely used in the medical field, such as detecting viruses, bacteria, gene mutations, etc. The optical lens sleeve system can realize accurate detection and quantitative analysis of PCR products and help diagnose diseases in medicine.

- Application of PCR optical lens tube system in biological science:

PCR technology is also widely used in the field of biological sciences, such as in genetic engineering and biomedical research. The optical lens tube system can help researchers observe and analyze PCR products more accurately, improving research accuracy and efficiency.

- Application of PCR optical lens tube system in environmental monitoring:

PCR technology can also be used in environmental monitoring, such as detecting pollutants in environmental samples such as water and soil. The optical lens tube system can realize accurate detection and quantitative analysis of PCR products, and help environmental monitoring personnel to detect and diagnose pollutants more accurately.

- Application of optical lens tube system in microscopes, telescopes and other optical instruments:

The optical lens tube system can be used in optical instruments such as microscopes and telescopes to improve imaging quality and reduce optical distortion. This has great significance for scientific research and engineering applications.