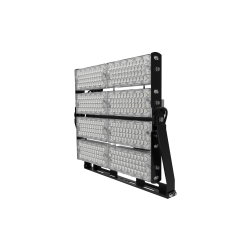

High Mast Light | TFD SERIES | High mast lighting

OVERVIEW

PRODUCT

| PRODUCT | RANK NO. | NOMINAL | SIZE | POWER | VOLTAGE | FLUX | EFFECT | CRI | IP | TYPICAL | PART NUMBER |

| (CCT/k) | (mm) | (W) | (VF/V) | (lm) | (LM/W) | (Ra) | DEG | ||||

| FSHEGM120VA2 | HMLEGMA01 | 3000K | 309*116*190 | 120 | 220 | 14400 | 120 | 80↑ | IP65 | 90° | 9405500000FL031 |

| FSHEGM120TA2 | HMLEGMA02 | 4000K | 309*116*190 | 120 | 220 | 14400 | 120 | 80↑ | IP65 | 90° | 9405500000FL032 |

| FSHEGM120RA2 | HMLEGMA03 | 5000K | 309*116*190 | 120 | 220 | 14400 | 120 | 80↑ | IP65 | 90° | 9405500000FL033 |

| FSHEGM120PA2 | HMLEGMA04 | 6000K | 309*116*190 | 120 | 220 | 14400 | 120 | 80↑ | IP65 | 90° | 9405500000FL034 |

| FSHEGM240VA2 | HMLEGMA05 | 3000K | 362*132*343 | 240 | 220 | 28800 | 120 | 80↑ | IP65 | 90° | 9405500000FL035 |

| FSHEGM240TA2 | HMLEGMA06 | 4000K | 362*132*343 | 240 | 220 | 28800 | 120 | 80↑ | IP65 | 90° | 9405500000FL036 |

| FSHEGM240RA2 | HMLEGMA07 | 5000K | 362*132*343 | 240 | 220 | 28800 | 120 | 80↑ | IP65 | 90° | 9405500000FL037 |

| FSHEGM240PA2 | HMLEGMA08 | 6000K | 362*132*343 | 240 | 220 | 28800 | 120 | 80↑ | IP65 | 90° | 9405500000FL038 |

| FSHEGM360VA2 | HMLEGMA09 | 3000K | 362*132*475 | 360 | 220 | 43200 | 120 | 80↑ | IP65 | 90° | 9405500000FL039 |

| FSHEGM360TA2 | HMLEGMA10 | 4000K | 362*132*475 | 360 | 220 | 43200 | 120 | 80↑ | IP65 | 90° | 9405500000FL040 |

| FSHEGM360RA2 | HMLEGMA11 | 5000K | 362*132*475 | 360 | 220 | 43200 | 120 | 80↑ | IP65 | 90° | 9405500000FL041 |

| FSHEGM360PA2 | HMLEGMA12 | 6000K | 362*132*475 | 360 | 220 | 43200 | 120 | 80↑ | IP65 | 90° | 9405500000FL042 |

| FSHEGM480VA2 | HMLEGMA13 | 3000K | 362*132*597 | 480 | 220 | 57600 | 120 | 80↑ | IP65 | 90° | 9405500000FL043 |

| FSHEGM480TA2 | HMLEGMA14 | 4000K | 362*132*597 | 480 | 220 | 57600 | 120 | 80↑ | IP65 | 90° | 9405500000FL044 |

| FSHEGM480RA2 | HMLEGMA15 | 5000K | 362*132*597 | 480 | 220 | 57600 | 120 | 80↑ | IP65 | 90° | 9405500000FL045 |

| FSHEGM480PA2 | HMLEGMA16 | 6000K | 362*132*597 | 480 | 220 | 57600 | 120 | 80↑ | IP65 | 90° | 9405500000FL046 |

| FSHEGM720VA2 | HMLEGMA17 | 3000K | 362*132*861 | 720 | 220 | 86400 | 120 | 80↑ | IP65 | 90° | 9405500000FL047 |

| FSHEGM720TA2 | HMLEGMA18 | 4000K | 362*132*861 | 720 | 220 | 86400 | 120 | 80↑ | IP65 | 90° | 9405500000FL048 |

| FSHEGM720RA2 | HMLEGMA19 | 5000K | 362*132*861 | 720 | 220 | 86400 | 120 | 80↑ | IP65 | 90° | 9405500000FL049 |

| FSHEGM720PA2 | HMLEGMA20 | 6000K | 362*132*861 | 720 | 220 | 86400 | 120 | 80↑ | IP65 | 90° | 9405500000FL050 |

| FSHEGMB480VA2 | HMLEGMB21 | 3000K | 649*133*343 | 480 | 220 | 67200 | 140 | 80↑ | IP65 | 90° | 9405500000FL051 |

| FSHEGMB480TA2 | HMLEGMB22 | 4000K | 649*133*343 | 480 | 220 | 67200 | 140 | 80↑ | IP65 | 90° | 9405500000FL052 |

| FSHEGMB480RA2 | HMLEGMB23 | 5000K | 649*133*343 | 480 | 220 | 67200 | 140 | 80↑ | IP65 | 90° | 9405500000FL053 |

| FSHEGMB480PA2 | HMLEGMB24 | 6000K | 649*133*343 | 480 | 220 | 67200 | 140 | 80↑ | IP65 | 90° | 9405500000FL054 |

| FSHEGMB720VA2 | HMLEGMB25 | 3000K | 649*133*475 | 720 | 220 | 100800 | 140 | 80↑ | IP65 | 90° | 9405500000FL055 |

| FSHEGMB720TA2 | HMLEGMB26 | 4000K | 649*133*475 | 720 | 220 | 100800 | 140 | 80↑ | IP65 | 90° | 9405500000FL056 |

| FSHEGMB720RA2 | HMLEGMB27 | 5000K | 649*133*475 | 720 | 220 | 100800 | 140 | 80↑ | IP65 | 90° | 9405500000FL057 |

| FSHEGMB720PA2 | HMLEGMB28 | 6000K | 649*133*475 | 720 | 220 | 100800 | 140 | 80↑ | IP65 | 90° | 9405500000FL058 |

| FSHEGMB960VA2 | HMLEGMB29 | 3000K | 649*133*597 | 960 | 220 | 134400 | 140 | 80↑ | IP65 | 90° | 9405500000FL059 |

| FSHEGMB960TA2 | HMLEGMB30 | 4000K | 649*133*597 | 960 | 220 | 134400 | 140 | 80↑ | IP65 | 90° | 9405500000FL060 |

| FSHEGMB960RA2 | HMLEGMB31 | 5000K | 649*133*597 | 960 | 220 | 134400 | 140 | 80↑ | IP65 | 90° | 9405500000FL061 |

| FSHEGMB960PA2 | HMLEGMB32 | 6000K | 649*133*597 | 960 | 220 | 134400 | 140 | 80↑ | IP65 | 90° | 9405500000FL062 |

| FSHEGMB1200VA2 | HMLEGMB33 | 3000K | 649*133*729 | 1200 | 220 | 168000 | 140 | 80↑ | IP65 | 90° | 9405500000FL063 |

| FSHEGMB1200TA2 | HMLEGMB34 | 4000K | 649*133*729 | 1200 | 220 | 168000 | 140 | 80↑ | IP65 | 90° | 9405500000FL064 |

| FSHEGMB1200RA2 | HMLEGMB35 | 5000K | 649*133*729 | 1200 | 220 | 168000 | 140 | 80↑ | IP65 | 90° | 9405500000FL065 |

| FSHEGMB1200PA2 | HMLEGMB36 | 6000K | 649*133*729 | 1200 | 220 | 168000 | 140 | 80↑ | IP65 | 90° | 9405500000FL066 |

| FSHEGMB1500VA2 | HMLEGMB37 | 3000K | 649*133*861 | 1500 | 220 | 210000 | 140 | 80↑ | IP65 | 90° | 9405500000FL067 |

| FSHEGMB1500TA2 | HMLEGMB38 | 4000K | 649*133*861 | 1500 | 220 | 210000 | 140 | 80↑ | IP65 | 90° | 9405500000FL068 |

| FSHEGMB1500RA2 | HMLEGMB39 | 5000K | 649*133*861 | 1500 | 220 | 210000 | 140 | 80↑ | IP65 | 90° | 9405500000FL069 |

| FSHEGMB1500PA2 | HMLEGMB40 | 6000K | 649*133*861 | 1500 | 220 | 210000 | 140 | 80↑ | IP65 | 90° | 9405500000FL070 |

FEATURES

1. The height of High Mast Light is 15-30 meters. The light pole adopts polygonal (usually 8 sides/12 sides/16 sides) pull-pin rod and plug-in structure (under 20 meters, it is divided into two sections, and the wall thickness is 6mm/8mm; 25 meters to 30 meters are divided into three sections (wall thickness 6/8/10mm). The plug length is 1.5 times the diameter of the plug end. The lamp panel is a frame structure; the bottom flange is round.

2. The electrical appliance door has a reasonable operating space, and there are electrical installation accessories inside the door; the gap between the door and the rod should not exceed 1 mm, and it has good waterproof performance; it has a special fastening system and has good anti-theft performance, and its fixing bolts Use non-general purpose tools to open.

3. Material

High Mast Light is made of high-quality low-silicon carbon steel Q235A steel (Si≤0.04%, yield strength >245Mpa), and the material complies with the executive standard: GB699-88.

4. Welding process

The entire rod body should be free of cracks, missing welds, continuous pores, undercuts, etc., and the welds should be smooth and flat, without undulations, or any welding defects. A welding flaw detection report must be provided. The welding standard is based on: GB/T3323-1989III. Safety standards comply with national standard GB7000.1-7000.5-1996.

5. Hot dip galvanizing process

The internal and external surfaces should be treated with hot pickling and corrosion treatment. The thickness should be ≥75um and comply with the GB-/T13912-92 standard. The designed service life should be no less than 30 years. The galvanized surface should be smooth and beautiful, with basically the same color, and should not peel or peel after the hammer test. Provide galvanizing test report.

6. Spray molding process

Plastic spraying should use outdoor pure polyester plastic powder, the color is white, the quality of the plastic layer is stable, it will not fade or fall off. It has strong adhesion, resists strong solar ultraviolet rays, and is resistant to ultraviolet rays, making it suitable for cities along lakes and key saline areas. The design service life is less than 30 years, the thickness is ≥80um, and it meets the ASTM D3359-83 standard. Provide spray testing report. Plastic spray protection requirements: film thickness should be no less than 40um, strong adhesion, no peeling or peeling from blade scratches (15*6mm square). The surface is flat and smooth, and the color is basically the same.

7. Design ability

a. According to the corresponding wind speed requirements, provide a pole stress calculation sheet based on the light pole shape drawing.

b. The strength and surface structure of the formed square steel used in the rod body must comply with the corresponding national standards.

C. Seal the light pole and wrap the top to prevent moisture from entering.

8. Verticality inspection

After the light pole is erected, use a theodolite to check the verticality between the light pole and the horizontal. The verticality should be less than or equal to three thousandths.

9. Feeling of the rod body

The shape and size meet the requirements, the overall appearance is beautiful and elegant, the surface of the rod body is smooth and consistent, and the color is uniform. The galvanized layer is smooth and flat, and the plastic spray layer has strong adhesion and will not peel off.

10. All fixing bolts, nuts, etc. are made of stainless steel (except anchor bolts and nuts).

11. The cable threading channel inside the light pole is unobstructed and easy to thread. There are no sharp edges, burrs, teeth or similar things to avoid damaging the cables.

12. The light pole meets the requirements for lightning protection and grounding. 2. Ambient temperature: -15-50 degrees Celsius; Ambient wind speed: 36m/s; Earthquake resistance intensity: 8 levels; Corrosion resistance level: 30 years.

BENEFITS

The lifting type High Mast Light has two lifting control modes, manual and electric, so that the lamp panel can be lowered to 2.5 meters above the ground safely and reliably, making maintenance easier.

The length of the lead wire of the manual remote control device is 10 meters, and the operator can remotely control the lifting and lowering of the lamp panel at a distance of 5 meters, which ensures the personal safety of the operator. The lifting high pole lamp is also equipped with a spare cable. When the lamp panel is lowered to the lowest position, one end of the cable is inserted into the socket of the electrical control system, and the other end is inserted into the junction box on the lamp panel, so that the lamp panel can be directly powered. , maintenance of lamps. The sealing level of all lamps of the lift-type high pole lamp is IP65 international standard to prevent the infiltration of dust and rainwater and ensure the service life of the bulb.

Lifting system part of High Mast Light

- The lifting system adopts an independent electric winch mechanism built into the light pole, and the winch is equipped with a special stop and lock device.Remote operation up to 5 meters away can be achieved through wire control;

- An adjustable and independent torque limiter is installed between the power tool and the winch to prevent overload;

- The high pole lamp adopts an electric lifting mechanism, which can be moved electrically. It is required to be operated manually when the power is cut off.

- The lifting system should use highly flexible stainless steel wire ropes, and the design safety factor is required to be no less than 6;

- The lifting mechanism is equipped with a device to prevent the light stand from falling off to ensure that the light stand is stuck in time and does not fall off when the wire rope breaks.

High Mast Light activity section

- The lamp panel is a steel frame structure, which has been treated with overall hot-dip galvanizing for anti-corrosion. It is required to have sufficient structural strength and can be easily disassembled and installed. All connectors are made of stainless steel;

- The light row structural connectors, basic bolts and nuts, etc. are all made of stainless steel;

- The lamp panel has a circular frame structure and the lighting is evenly distributed;

- The lamp panel must be reliably positioned when it reaches the use position, and the maintenance required by the positioning system should be close to zero. A travel switch is added to the upper limit of the lamp panel;

- Maintenance work on lamps should be completed on the ground.

Lift-type high pole lamp part:

- The floodlight lamp adopts aluminum die-casting shell. The material is industrial pure aluminum L2 and complies with: GB3190-82. The lamp is an integrated design with an independent light source room and an isolated electrical room. The surface is treated with imported powder spraying and is resistant to ultraviolet radiation.

- The lamp is sealed with a new type of silicone rubber sealing ring, which can withstand high temperatures above 250°C, effectively ensuring that the silicone rubber does not age. The long-term protection level is IP65, and the electrical level is class I. It adopts an easy-to-operate, safe and reasonable buckle seal, and the buckle material is stainless steel.

- The shape of the reflector ensures the requirements of the light distribution curve, without cracks and clear texture. Oxidation treatment: The surface is smooth, uniform, and has a high reflection coefficient, ensuring that the luminous efficiency of the lamp reaches more than 80%. The surface has high hardness and is not easy to be scratched.

- The light-transmitting cover is made of high-strength tempered transparent glass, which requires high temperature resistance above 250°C, high light transmittance, and impact resistance.

- The lamp is equipped with a live carbon fiber respirator to ensure air circulation and prevent dust from entering the reflective port. The lamp holder adopts an elastic structure and has excellent shock-proof performance. The lamp holder adopts a rotating sealed lamp holder, and the electrical appliance must be designed and installed inside the lamp.

- The lamps meet the requirements for lightning protection and grounding. Pay attention to the basic conditions and working environment of the area. Ambient temperature: -15-50 degrees Celsius; Ambient wind speed: 36m/s; Earthquake resistance intensity: Level 6; Corrosion resistance level: 20 years, components The design and manufacturing (construction) technology complies with national standards.

Lifting High Mast Light electrical system part

- The electrical part of the high pole lighting system adopts single-phase split-phase (three-phase) control. Each phase is equipped with a separate circuit breaker and contactor. The contactor coil adopts AC 220V. Each high pole light can be controlled locally. and centralized remote control;

- Power supply: 50Hz, AC three-phase five-wire system, 380V/220V;

- The power distribution control box of high pole lights should have overload, short circuit and leakage protection;

- Circuit breakers, leakage protectors, and contactors must be equipped with auxiliary contacts, and the auxiliary contacts must be led to the terminal blocks;

- Various power supply cables in the high pole are reliably connected to the steel wire rope through special clamps, and rise and fall together with the steel wire rope, without bearing the weight themselves. The lighting power supply cable uses YC high-quality heavy-duty rubber sheathed cable;

- The high pole lamp should be equipped with one 400V, 32A socket and one 230V, 16A socket for maintenance. The sockets should be protected by circuit breakers;

- The connection between the lighting power supply cable on the top of the light pole and the lamp cable should be equipped with a junction box, and the protection level of the junction box should reach IP65;

High Mast Light Instructions for Use

In the rectangular inner cavity at the bottom of the lift-type high pole lamp, in addition to the electrical control system, a motor and other lifting systems are also installed. The electrical control system is installed inside the light pole to avoid failures in the lifting movement caused by harsh outdoor environments. Various circuit overload protection devices are installed in the electrical control system.

The conductors of the circuits in the system are widely plated with copper-based silver to ensure good electrical connections. The lifting system of the lifting high pole lamp drives the lifting and lowering of the lamp panel through components such as a motor, (electromagnetic braking) worm gear reducer, safety coupling, main wire rope, auxiliary wire rope, rope divider and movable pulley group. The worm gear reducer has strong self-locking ability, compact transmission, and large transmission ratio. In order to reduce the worm gear and worm gear ratio and reduce the rising torque, a set of moving pulleys are specially added to make the lifting speed of the lamp panel less than 0.2 meters/second. .

The main steel wire rope is connected to the auxiliary steel wire rope of the lamp panel through a rope splitter, which can avoid the entanglement of the auxiliary steel wire due to the stretching of the main steel wire. The main and auxiliary steel wire ropes are made of high-strength, corrosion-resistant 6*19 type non-rotating galvanized steel wire ropes. The lifting pulleys all use hot-dip galvanized A3 steel brackets, stainless steel shafts, and copper pulleys to ensure that they will not rust under normal atmospheric conditions and operate flexibly.

Various fastener washers, clamp rings and other parts are also made of hot-dip galvanized parts or stainless steel. The lamp panel is equipped with 6 sets of guide pulleys and more than three sets of braking devices. When the lamp panel is raised or lowered, the guide wheels distributed at 120 degrees roll along the surface of the lamp pole to ensure that the lamp panel does not swing. The surface of the working part where the guide wheel of the lamp panel is in contact with the surface of the lamp pole adopts rubber hot pressing process. In order to fully ensure that the lamp panel automatically stops when it reaches the extreme position, the lamp panel is equipped with reliable limit switches for its rising and falling movements, and is equipped with over-travel protection.

The lifting and lowering of the high pole lamp panel is achieved by changing the rotation direction of the motor. For security and anti-theft purposes, the rectangular cavity is equipped with a sealed door, and a special door lock is installed on the sealed door.

APPLICATION

High Mast Light is a special street light with a height usually above 15 meters. It is suitable for squares, parks, highways, airports, docks, stations and other places. In addition to being a lighting device, it also has the following characteristics and uses: